| Machine weight | About 2000kg |

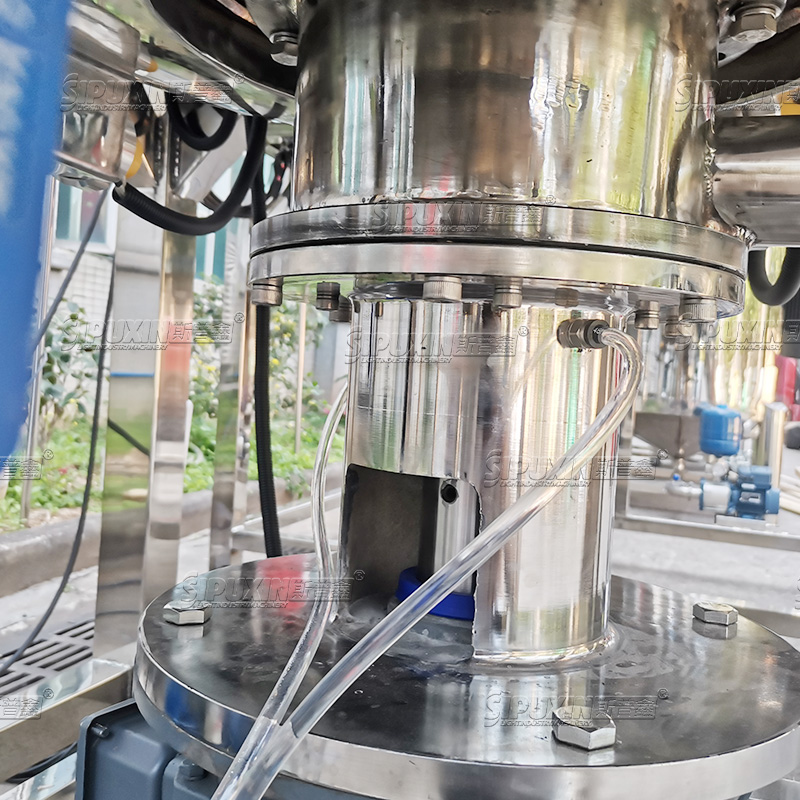

| Product name | Liquid soap /cosmetic paste cream making machine |

| Material | SUS304/316L |

| Function | Homogenizing and mixing machine |

| Driven Type | Steam or Electric heating |

| Type | Homogenizer and mixing, Heating, Emulsifier |

| Advantage | Customized |

1. Pitting corrosion of stainless steel reactor: Pitting corrosion refers to the appearance of small holes on the metal, forming a form of local corrosion, which mainly appears in the upper part of the reactor, because there is a liquid droplet and gaseous medium in the upper part of the reactor, which has poor fluidity. And those droplets contain high concentrations of corrosive media, which destroy the protective film of the metal and form pitting corrosion.

2. Stress corrosion of the lower head: Stress corrosion of the lower head refers to the brittle fracture, fatigue, and corrosion cracking of the head due to the residual stress of cold processing in production, which causes the inner surface to be pulled and the outer surface to be compressed. The residual stress comes from the production of the head. The head is produced by spinning. The head produced by spinning is prone to uneven plastic deformation during cold processing.

3. Stainless steel lining corrosion: Stainless steel lining corrosion refers to the obvious pits on the lining after the rupture, which vary in depth and uneven distribution. Lining corrosion is caused by high temperature, high pressure and strong corrosive media.

4. Corrosion of stainless steel reactor: The corrosion of steam reactor refers to the corrosive gas generated by the material when the material is steam-pressed, coupled with the high pressure, high temperature, and frequent alternation of hot and cold in the kettle.

The corrosion of stainless steel reactor can be avoided, so when processing products, pay attention to the characteristics of the material and take anti-corrosion measures according to the material.

English

English