| Machine weight | About 2000kg |

| Product name | Liquid soap /cosmetic paste cream making machine |

| Material | SUS304/316L |

| Function | Homogenizing and mixing machine |

| Driven Type | Steam or Electric heating |

| Type | Homogenizer and mixing, Heating, Emulsifier |

| Advantage | Customized |

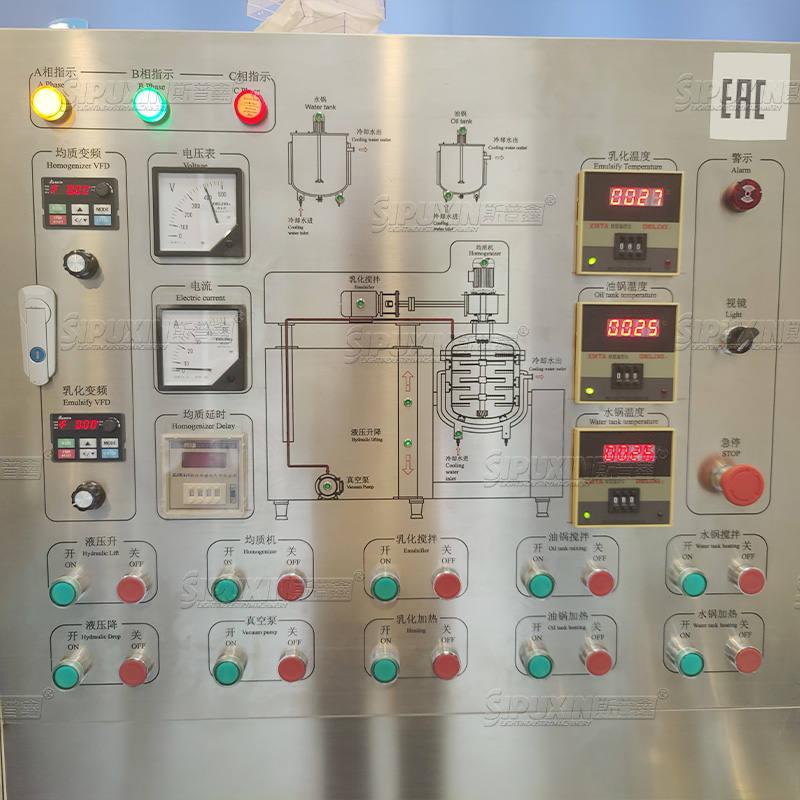

The inspection contents of the hydraulic oil of the vacuum emulsifier mainly include the following points:

1. The cleanliness, color, viscosity and consistency of the hydraulic oil, as well as the smell.

2. When the hydraulic oil flows from the high-pressure side to the low-pressure side without doing mechanical work, heat will be generated in the hydraulic system.

3. If the hydraulic oil temperature is too high, it will cause the expensive seals to deteriorate and the oil to oxidize to failure, which will cause corrosion and deposits to form, and even block the damping hole and accelerate the wear of the valve. Excessive temperature will cause the valve and pump to jam, and high temperature will also bring safety problems.

4. With the help of checking the oil temperature in the oil tank, sometimes the system fault can be eliminated before serious harm occurs.

5. In most vacuum emulsifier systems, the overflow valve is the main source of heat, and the excessive flow through the pressure reducing valve is another major cause of heat.

English

English