1T Combination Steam Heating Vacuum Homogeneous emulsifiying Machine key features:

Product name:1T Combination Steam Heating Vacuum Homogeneous emulsifiying Machine

Stirring Mixing Way:One-way Frame

Open way:Hydraulic Lifting

Heating Method:Electric/Steam Heating

Vacuum:-0.09

Application scope:High Viscosity Product:cosmetic,food,Chemicals

Discharging Ways:Positive pressure discharging or dumping of discharging

Homogenizer Speed:0-3600 R/min

Stirring speed:0-65 R/min

After-sales Service Provided:Overseas Service Provided

Production description:

Introducing the 1T Combination Steam Heating Vacuum Homogeneous emulsifiying Machine, the ultimate

solution for your high-quality emulsifying and mixing needs. This fixed combination vacuum homogenizing

emulsifier features an increased capacity with the addition of a combination tank, allowing for faster heating with

steam heating compared to electric heating, saving you valuable time in the production process. Perfect for

emulsifying and mixing creams and other high-viscosity products, this machine guarantees a smooth and

consistent texture every time. Choose the 1T Combination Steam Heating Vacuum Homogeneous emulsifiying

Machinefor efficient and reliable production of your top-quality products.

Production details:

Top Accessories

These accessories have many functions,such as:1.Sight glass device,2.Suction device,3. Vacuum induction device,4.Vacuum device,5.Sight glass lamp,6.Breathing device,7.Cleaning device,8.Vacuum pressure gauge.

They can well perform tasks such as observation and mixing during the production process.

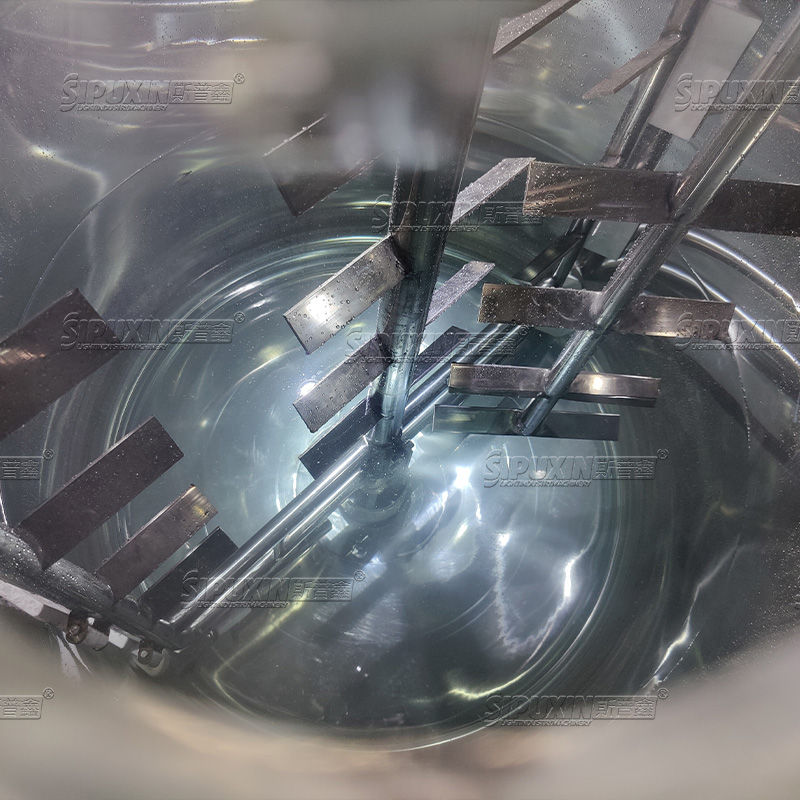

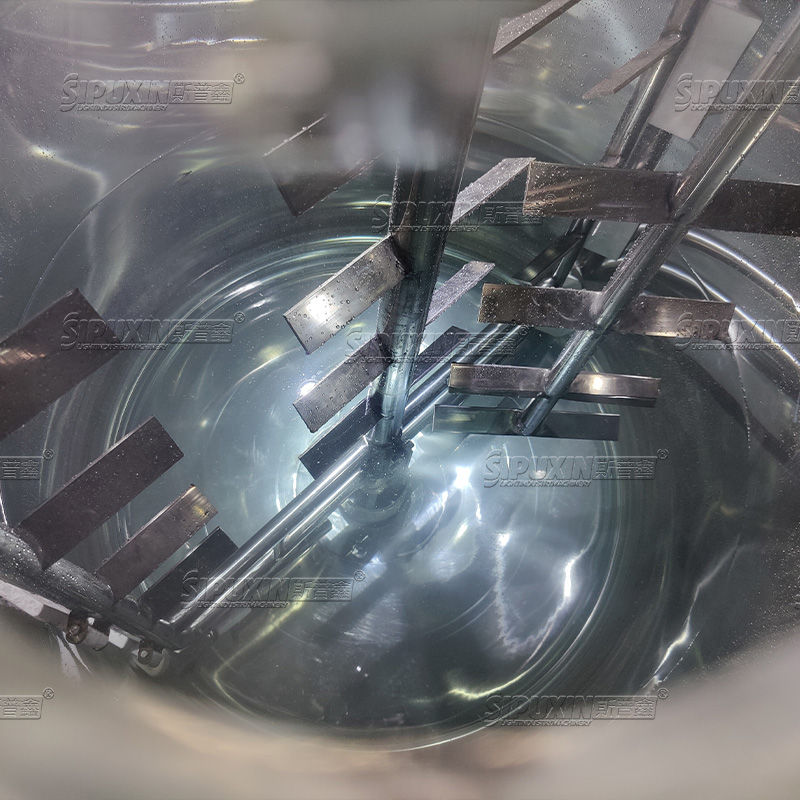

The mixing system

The wall scraping and bottom stirring paddle is equipped wiith a Teflon plate, equipped with a side fixed slurry. The mixing system consists of inter fix paddle,scrapper mixer and clockwise direction blender,which top wall-scraper mixer 0-60RPM and bottom homogenizer0-3000RPM.and the perfect mixing result increase the mixing efficiency and performance,as well as heating efficiency

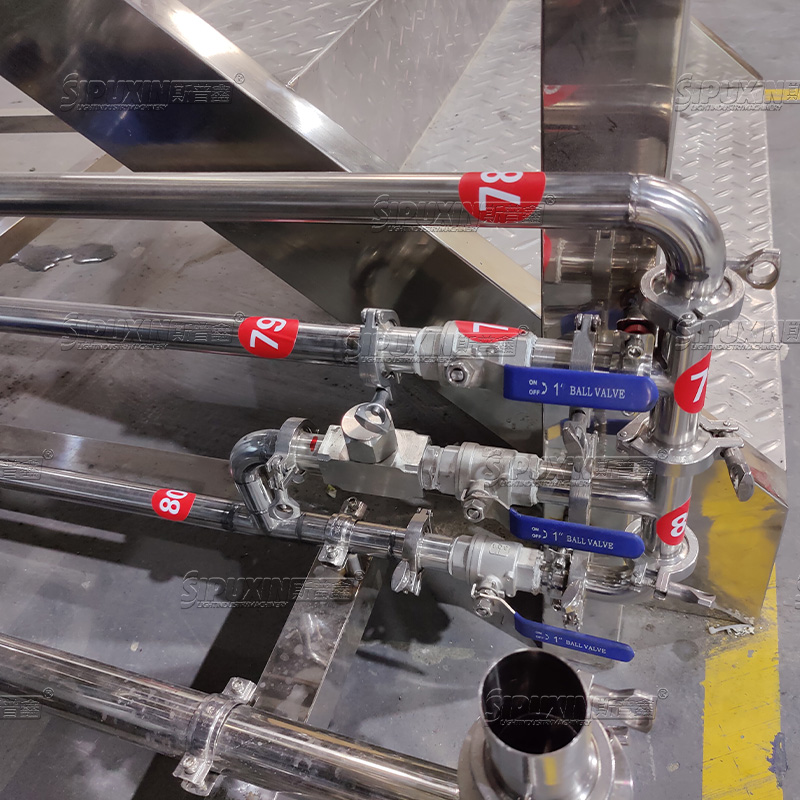

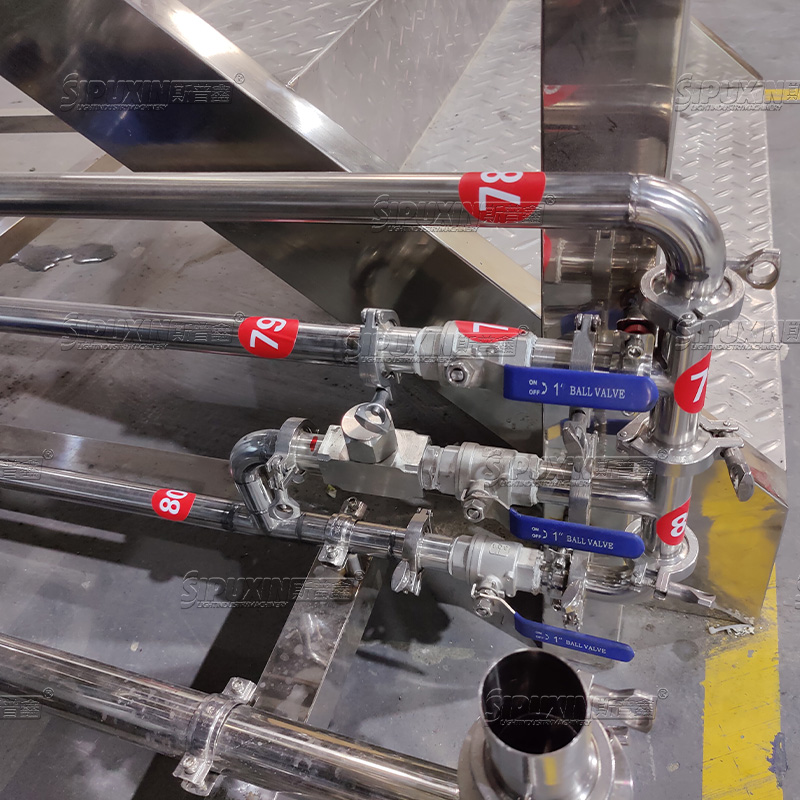

Various pipes

The steam-heated vacuum homogeneous emulsifier is equipped with various pipes, including heating pipes, sewage pipes, etc.

Homogenizer

Homogenizer consists of motor, stator and rotor,use high-speed rotor to break the material,the material liquid is refined and mixed under the triple action of extrusion,strong impact and loss of pressure expansion.Homogenizing under high pressure can significantly refine the fat globules in looseness of the liquid material.

English

English