10L Cosmetic Mixer Vacuum Homogenizer Mixing Emulsifier Tank key features:

Product name:10L Horizontal bar hydraulic vacuum homogeneous emulsifier

Function:Homogenzing and emulsifying

Heating method:Electric Heating

Control:Button Panel

Homogenizer Speed:0-3000 R/min

Stirring speed:0-65 R/min

Keyword:Vaccum homogenizing emulsifier

Application scope:cosmetic,food,Chemicals

Type:Homogenizer Making Machine

Application scope:cosmetic,food,Chemicals

After-sales Service Provided:Overseas Service Provided

Production description:

Introducing our professional-grade 10L Hydraulic Lifting Vacuum Homogenizing Emulsifier, the

perfect solution for high-viscosity cream products such as eye cream, sunscreen, face cream, and lip

balm. Despite its compact size, this emulsifier delivers the same powerful performance as larger

models, making it an ideal choice for those seeking a more efficient and space-saving option. With its

advanced hydraulic lifting system, this emulsifier provides unparalleled precision and control over the

emulsification process, ensuring consistent and high-quality results every time. Invest in the best with

our 10L Hydraulic Lifting Vacuum Homogenizing Emulsifier and take your product development to

the next level.

Production details:

Top Accessories

These accessories have many functions,such as:1.Sight glass device,2.Suction device,3. Vacuum induction device,4.Vacuum device,5.Sight glass lamp,6.Breathing device,7.Cleaning device,8.Vacuum pressure gauge.

They can well perform tasks such as observation and mixing during the production process.

Button operation panel

Visual digital control, easy to identify buttons.The control panel is more convenient for the operator to operate various functions,and can adjust the fre- quency, start quickly,stop immediately, and is very sensitive

The mixing system

The wall scraping and bottom stirring paddle is equipped wiith a Teflon plate, equipped with a side fixed slurry. The mixing system consists of inter fix paddle,scrapper mixer and clockwise direction blender,which top wall-scraper mixer 0-60RPM and bottom homogenizer0-3000RPM.and the perfect mixing result increase the mixing efficiency and performance,as well as heating efficiency

Homogenizer

Homogenizer consists of motor, stator and rotor,use high-speed rotor to break the material,the material liquid is refined and mixed under the triple action of extrusion,strong impact and loss of pressure expansion.Homogenizing under high pressure can significantly refine the fat globules in looseness of the liquid material.

Vacuum pressure gauge

An observation and control system for monitoring and setting the vacuum degree inside a tank is a critical feature in many industrial processes, particularly in industries like pharmaceuticals, chemical manufacturing, food production, and scientific research. an observation and control system for monitoring and setting the vacuum degree inside a tank is a crucial component in industries where precise control over process conditions is essential for safety, product quality, and efficiency. It provides operators with the tools they need to optimize processes, maintain safety standards, and achieve consistent results.

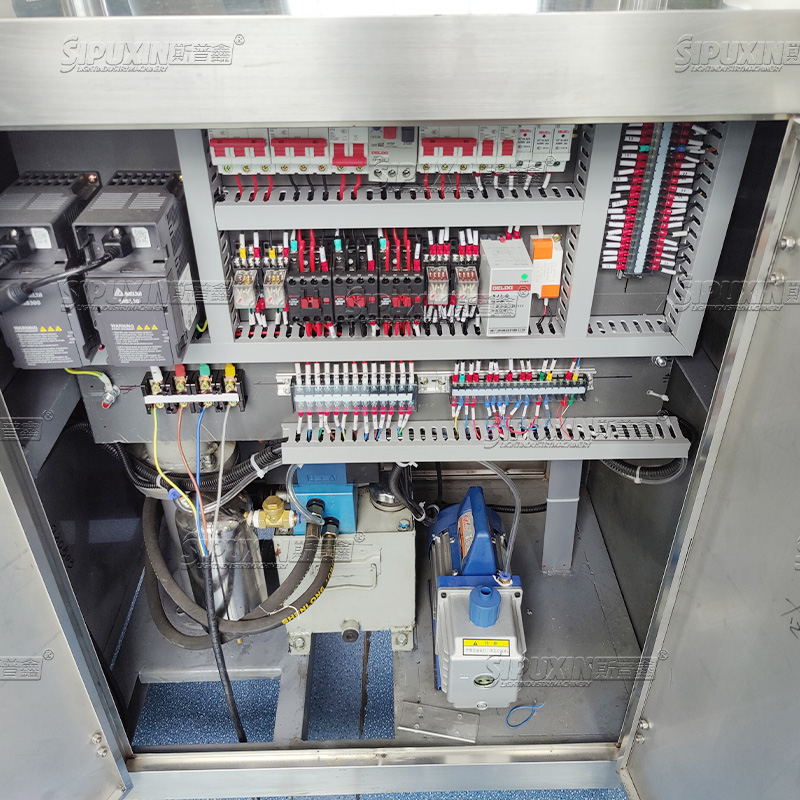

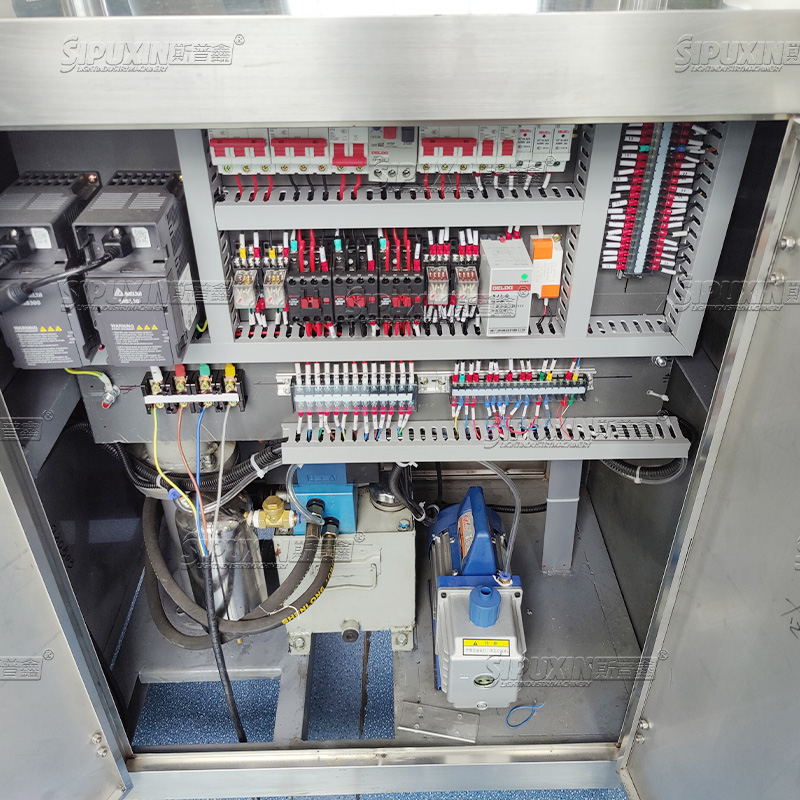

Electric box

Implementing a high-safety coefficient electrical box is a fundamental aspect of ensuring the safe and reliable operation of machinery and equipment in various industrial and commercial settings. a high-safety coefficient electrical box is a critical component of industrial and commercial equipment, ensuring the safety of both personnel and machinery. It offers protection against electrical faults, contributes to regulatory compliance, and provides peace of mind to all stakeholders involved in the operation and maintenance of equipment.

FAQ

Packing

English

English