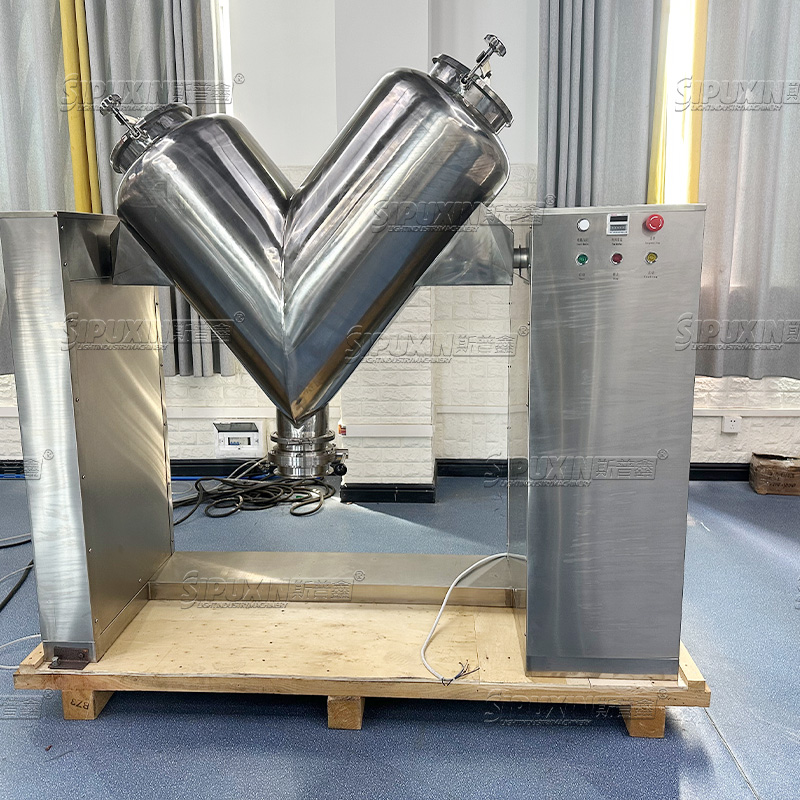

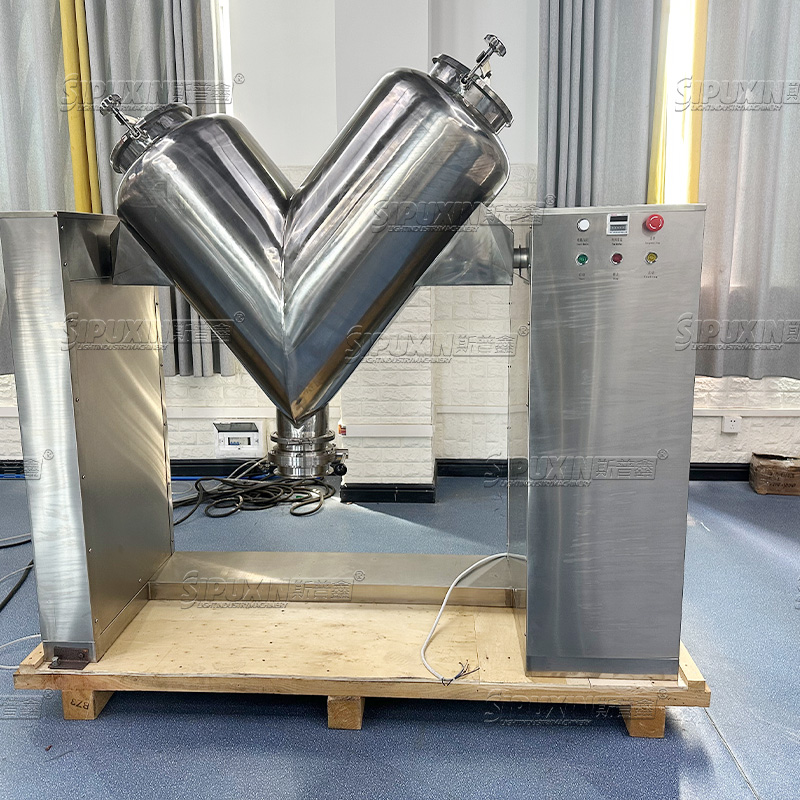

Introduction to SPX V-Shape Powder Mixer from Guangzhou SPX Light Industrial Machinery Equipment Co., Ltd.

Guangzhou SPX Light Industrial Machinery Equipment Co., Ltd. is pleased to introduce our SPX V-Shape Powder Mixer – a versatile and efficient solution for mixing powders in various industries.

Features & Benefits:

- V-shape design provides better mixing efficiency, reducing mixing time and improving consistency.

- Two asymmetric blades rotate in opposite directions to create a double circulating flow, ensuring a thorough and homogeneous mixing result.

- Constructed with high-quality stainless steel, the mixer is corrosion-resistant and easy to clean.

- Airtight mixing chamber and advanced sealing technology prevent powder leakage and cross-contamination.

- Available in various sizes and configurations to meet different production needs.

Applications:

- Pharmaceutical industry: mixing of powders, granules, and particles for tablet pressing, capsule filling, and other processes.

- Food industry: blending of food powders, spices, seasonings, and additives for baking, flavoring, and processing.

- Chemical industry: mixing of different powders and chemicals for manufacturing, research, and development.

- Other industries: cosmetics, ceramics, metallurgy, etc.

Conclusion:

With our SPX V-Shape Powder Mixer, you can achieve excellent mixing results and save time and energy in your production process. Please contact us for more information and customized solutions to meet your specific requirements. We are committed to providing high-quality products and services to our customers worldwide. Thank you for choosing SPX!

Product Packaging

Click here to edit your content.

Click here to edit your content.

Click here to edit your content.

Click here to edit your content.

Comment & FAQ

"Our company, Guangzhou Spuxin Light Industry Machinery Equipment Co., Ltd., has received excellent feedback from our customers regarding our products. They have praised our innovative designs, superior quality, and reliable performance. Our customers appreciate our commitment to providing efficient and cost-effective solutions for their light industry needs. We are proud to have earned such high praise from our valued clients and will continue to strive for excellence in all aspects of our business."

1. What is Guangzhou Supuxin Light Industrial Machinery Equipment Co., Ltd. all about?

2. What products does Guangzhou Supuxin Light Industrial Machinery Equipment Co., Ltd. manufacture?

3. What kind of services does Guangzhou Supuxin Light Industrial Machinery Equipment Co., Ltd. provide?

4. Does Guangzhou Supuxin Light Industrial Machinery Equipment Co., Ltd. customize its products?

5. What are the payment terms for Guangzhou Supuxin Light Industrial Machinery Equipment Co., Ltd.?

6. What is the lead time for orders from Guangzhou Supuxin Light Industrial Machinery Equipment Co., Ltd.?

7. Does Guangzhou Supuxin Light Industrial Machinery Equipment Co., Ltd. offer after-sales services?

8. What are the warranties for products from Guangzhou Supuxin Light Industrial Machinery Equipment Co., Ltd.?

9. Can I visit the factory of Guangzhou Supuxin Light Industrial Machinery Equipment Co., Ltd.?

10. What is the pricing policy of Guangzhou Supuxin Light Industrial Machinery Equipment Co., Ltd.?

Production Process

Certifications

CE certificate for blending mixer

CE certificate for vacuum emulsifier

Certification wall

CE certificate for semi-automatic labeling machine

More details show

Testing Quality

Guangzhou Spxin Light Industrial Machinery Equipment Co., Ltd. conducts machine quality testing through the following steps:

1. Visual inspection: the machine is visually inspected for any obvious defects or irregularities.

2. Functionality testing: the machine is run to test if it performs its intended functions and meets required specifications.

3. Durability testing: the machine is put through multiple cycles of use to test its endurance and reliability.

4. Safety testing: the machine is tested to ensure it meets safety standards and does not pose any potential hazards.

5. Quality control: a comprehensive quality control process is implemented to ensure the overall quality of the machine meets company and industry standards.

English

English

Click here to edit your content.

Click here to edit your content.