Perfume Pneumatic Dispenser Storage tank key features:

Product Name:Perfume Pneumatic Dispenser

Material:SUS304/316L

Usage:Perfume

Applicable in Industries:Perfume

Function:Industrial liquid storage tank

Packing:wood case

Thickness:Depend on the capacity

Key Selling Points:Low Maintenance Cost

Color:Sliver

Additional:Glass Tank Level Sight Glass

Production description:

Perfume Pneumatic Dispenser Function:

Alcohol, pigment and fragrance enter the tank through the flowmeter through the pipeline,

fully dissolve, mix and stand under the stirring driven by the air hole motor to achieve the ideal

fragrance and color.

Porduction details:

Wheels

Introducing our Perfume Pneumatic Dispersion with the convenience of four sturdy wheels. This thoughtful addition not only enhances the mobility of the device but also ensures that your workers can effortlessly transport it from one location to another. These robust wheels are designed to make your workplace more efficient, allowing your team to focus on their tasks without any hassle, all while ensuring that your perfume dispersion process remains smooth and seamles

Sealing cover

Our Sealing Cover not only ensures a secure enclosure but goes beyond that with its advanced features. Equipped with an integrated air filter and a powerful blending motor, it guarantees not only the containment of volatile substances but also the maintenance of product integrity inside the tank.

This Sealing Cover is the ultimate choice for businesses that prioritize product quality and safety. It's a testament to our commitment to innovation and excellence, providing you with peace of mind that your valuable products are in the best hands.

Blending mixing paddle

At the heart of this paddle's excellence is its remarkable stirring speed. It's designed to stir your mixtures rapidly and efficiently, saving you precious time while ensuring that every component is thoroughly blended. Whether you're working with liquids, powders, or other materials, our Blending Mixing Paddle guarantees uniform consistency, leaving no room for uneven mixes.

What sets this mixing paddle apart is its construction. Crafted from high-quality stainless steel 316, it's not only built to last but also highly resistant to corrosion and wear, making it an ideal choice for environments where hygiene and longevity are paramount. This stainless steel construction ensures that your paddle can stand up to even the most demanding mixing tasks, and it's easy to clean and maintain.

Discharge hole

The key feature of our Discharge Hole is its strategically placed on-off valve. This valve allows you to have complete command over the discharge process, ensuring that materials are released precisely when and where you need them. Whether you're working with bulk solids, liquids, or powders, this valve guarantees a controlled and efficient discharge, preventing waste and spillage.

Moreover, our Discharge Hole is engineered with the highest standards of quality and durability in mind. Crafted from robust materials, it's built to withstand the rigors of industrial applications while maintaining its performance over time. This reliability means you can trust our Discharge Hole to consistently deliver precise material discharge in your operations.

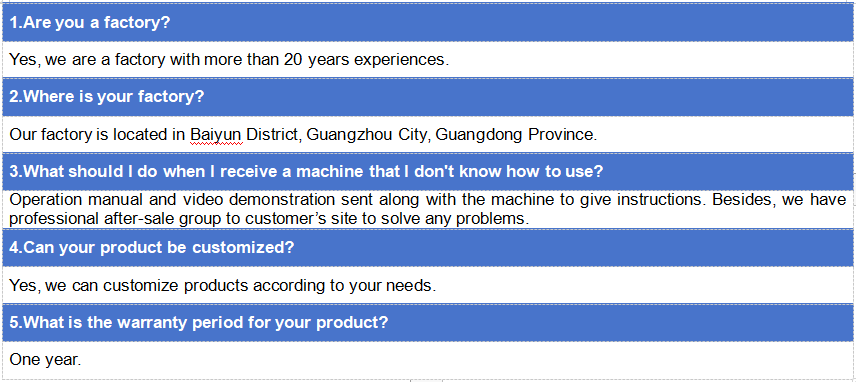

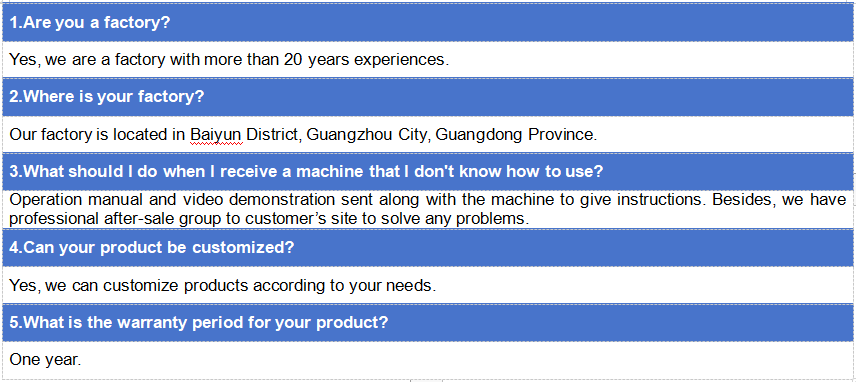

FAQ

Packing

English

English