Blending tank key features:

Machine name:Liquid Washing Making Machine

Capacity:1-5000L Customizable

Motor:Siemens

Color:Sliver

Advantage:High Efficieccy

Control:Botton

Function:High Shear Dispersing,Mixing, Heating and Cool, Homogenizing

Heating:Electric Heating or Steam Heating

Usage:Cosmetic Industry/Chemical Industry

Stirrer type:Unidirectional or Bidirectional

Production description:

500L Electric heating homogenizer mixing and dispering tank,Tank and pipe mirror,in line with GMP requirements.

function:

1. stirring system,stirring speed regulation,scapping wall stirring,using frequency conversion speed control.

2. Homogenizer system,homogenizer speed 0-3000rpm

3. Dispersing system,dispersion speed 0-1500rpm,disperse and dissolve the incompletely dissolve clumps in the liquid.

Electric heating homogenizer mixing and dispering tank is suitable for liquid detergent,food and cosmetic production.

Production details:

homogenizer motor

High-speed homogenization is a highly efficient and versatile process that facilitates the thorough mixing, emulsification, dispersion, and homogenization of products. By harnessing the power of rapid mechanical agitation, this method enables the complete integration of various components within the product, resulting in a uniform and consistent mixture. Through the application of intense shear forces and turbulence, the process breaks down particles, droplets, or substances that would otherwise remain separate or unevenly distributed.

During high-speed homogenization, the product undergoes a series of intricate interactions as it is subjected to vigorous mechanical forces. These forces cause the components to collide, intermingle, and merge at a microscopic level, leading to the creation of stable emulsions, finely dispersed particles, and a homogenous blend overall. This process is particularly beneficial for industries such as food, pharmaceuticals, and cosmetics, where achieving a consistent and high-quality end product is crucial.

Mixing paddle

This setup offers a dynamic and adaptable approach to the mixing and homogenization processes. The top wall-scraper mixer, operating within the range of 0 to 60 RPM, serves as a controlled and gradual mixer that effectively prevents sedimentation and ensures consistent blending of ingredients. Its gentle rotational motion along the upper surface of the mixture prevents the formation of dead zones and aids in maintaining uniformity, making it well-suited for delicate materials or situations where shear forces need to be minimized.

On the other hand, the bottom homogenizer, with its high-speed capability ranging from 0 to 3000 RPM, plays a pivotal role in rapidly and forcefully breaking down particles, promoting emulsification, and achieving thorough dispersion. The incorporation of a variable frequency drive (VFD) enhances the versatility of this homogenizer by allowing operators to precisely adjust the rotational speed to meet the specific requirements of the materials being processed. This flexibility makes it possible to tailor the level of shear and turbulence based on the viscosity, density, and nature of the substances involved, resulting in optimal mixing and homogenization outcomes.

Operation Panel

The operation panel is designed with functionality and user-friendliness in mind. It features a sturdy stainless steel construction, ensuring durability and resistance to corrosion. The visual digital control interface provides operators with clear and intuitive access to various functions, enhancing the overall user experience.

the stainless steel operation panel with its visual digital control, easy-to-identify buttons, and sensitive functionality provides operators with a convenient and efficient means of managing various functions. It empowers users to adjust frequencies precisely, start and stop equipment rapidly, and maintain a high level of control, making it an invaluable component for seamless and responsive operations in various industrial settings.

The "High Shear Disperse" equipment you've described offers a versatile and powerful solution for the dispersion and shearing of both liquid and solid raw materials. One of its key features is the adjustable speed, which allows operators to fine-tune the equipment's performance according to the specific requirements of their process.

The "High Shear Disperse" equipment with adjustable speed, ranging from 1 to 960 RPM, is a versatile and efficient solution for dispersing and shearing both liquid and solid raw materials. Its adaptability, combined with its ability to handle a wide range of materials, positions it as a valuable tool in industries where achieving consistent and high-quality mixtures is essential.

Two motor

The equipment employs high-quality motors, specifically Siemens or Motor, to drive its essential functions. This dual-motor setup, with one motor dedicated to stirring and the other to dispersing, enhances the versatility and efficiency of the equipment.

The use of Siemens or Motor motors, combined with the dual-motor setup—one for stirring and the other for dispersing—enhances the performance, reliability, and flexibility of your equipment. This configuration allows for precise control over mixing and shearing operations, ensuring consistent and efficient processing of various materials across different industries.

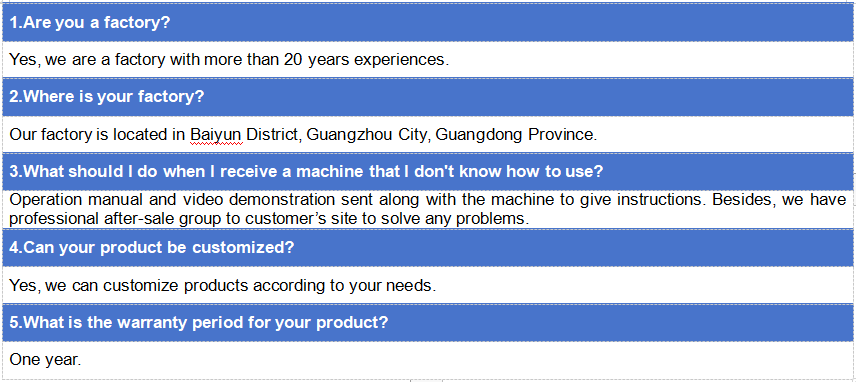

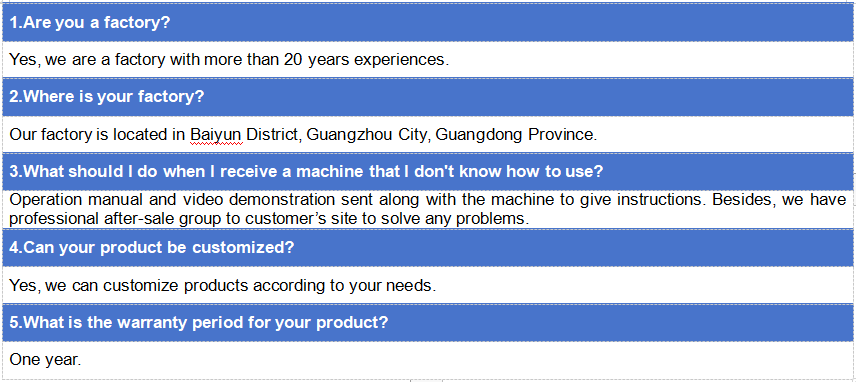

FAQ

Packing

English

English