300L Blending mixer key features:

Machine name:Liquid Blending Mixing Machine

Motor:Siemens

Color:Sliver

Advantage:High Efficieccy

Control:Button

Function:High Shear Dispersing,Mixing, Heating and Cool, Homogenizing

Heating:Electric Heating or Steam Heating

Usage:Cosmetic Industry/Chemical Industry

Stirrer type:Unidirectional or Bidirectional

Production description:

Introducing the 300L Electric Heating Homogeneous Stirring Pot, a versatile and efficient addition to any industrial kitchen. With its advanced features, this high-quality pot is designed to meet the demands of modern food processing and manufacturing operations.

Equipped with both stirring and homogenizing capabilities, this pot allows you to achieve the perfect consistency for your products. The top stirrer can be adjusted to a variable frequency of 0-63rpm/min, while the bottom homogenizer can be adjusted to a variable frequency of 0-3000rpm/min. This means you can have complete control over the speed of your mixing and homogenizing, for precise results every time.

The pot is heated using an electric heating method and comes with a heating rod for efficient and effective heating. This ensures that your ingredients are evenly heated and that the cooking process is both fast and consistent.

The pot is also designed for easy mobility, with four wheels that make it easy to move around your workspace. This makes it perfect for use in large kitchens where mobility is key.

Overall, the 300L Electric Heating Homogeneous Stirring Pot is a must-have for any professional kitchen that values precision, efficiency, and ease of use. It is the perfect tool for producing high-quality food products and streamlining your production processes, helping you to save time and money.

Production details:

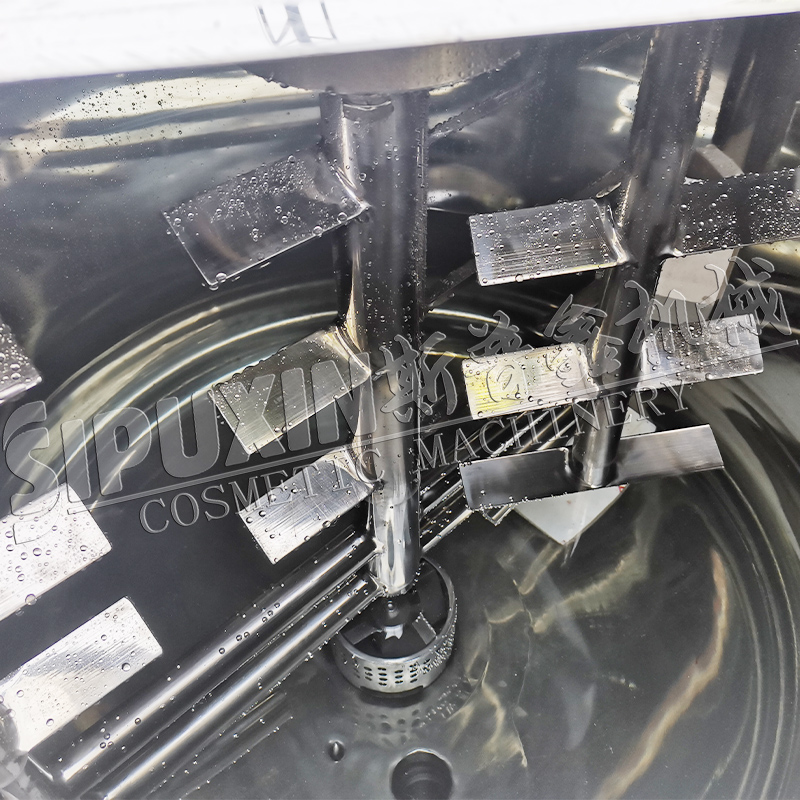

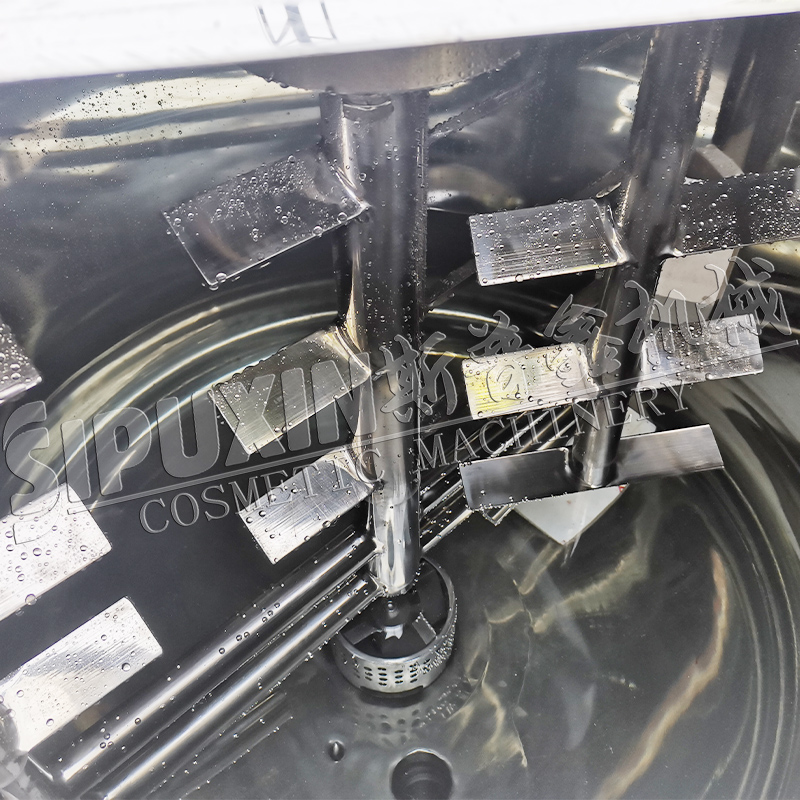

Homogenizer

High-speed homogenization is a critical process in various industries, including food, pharmaceuticals, cosmetics, and chemical manufacturing. It plays a vital role in achieving thorough mixing, emulsification, dispersion, and homogenization of products. Here's how high-speed homogenization contributes to these important functions:Mixing、Emulsification、Dispersion、Homogenization, high-speed homogenization is a versatile and essential process in various industries, providing the means to achieve product uniformity, stability, and desired characteristics. It is a fundamental step in the production of numerous products, ranging from food and beverages to pharmaceuticals and cosmetics, where the quality, texture, and performance of the final product depend on the effectiveness of the homogenization process.

Mixing paddle

The equipment includes a top wall-scraper mixer with a speed range of 0-60 RPM and a bottom homogenizer with a speed range of 0-3000 RPM and variable frequency drive (VFD) adjustability, is a versatile and efficient mixing system that finds applications in various industries. Here's a breakdown of its features and advantages:Dual Mixing Mechanisms、Speed Variability、Uniform Mixing、Emulsification and Dispersion、Versatility, the combination of a top wall-scraper mixer and a bottom homogenizer with speed variability and VFD adjustability offers a comprehensive mixing solution with the flexibility to handle a wide range of materials and processes. This equipment is a valuable asset in industries where precise mixing, emulsification, and dispersion are crucial for product quality and performance.

Operation Panel

A stainless steel operation panel with visual digital control and easily identifiable buttons is a highly practical and user-friendly feature, especially in industrial and commercial settings where precision, convenience, and durability are essential. Here's a closer look at the benefits and advantages of such a control panel:Durability、Visual Digital Control、Ease of Identification、Convenience、Sensitivity、Functionality、Safety,a stainless steel operation panel with visual digital control and easily identifiable buttons is a valuable feature that enhances the durability, convenience, and safety of equipment operation. It ensures that operators can perform their tasks efficiently, with precision, and with minimal effort, ultimately contributing to improved productivity and product quality.

|

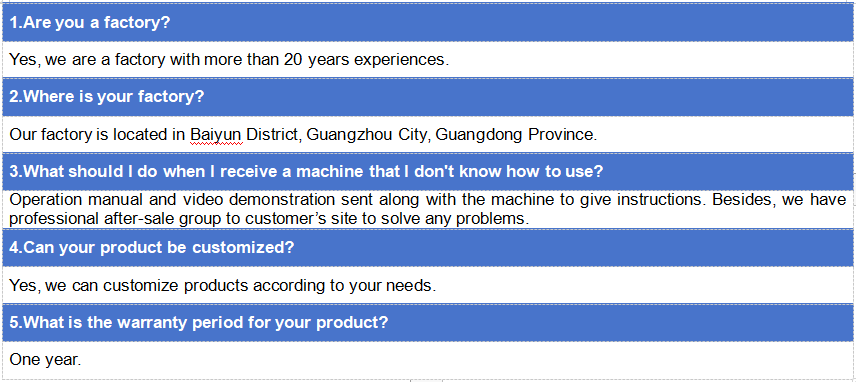

FAQ

|

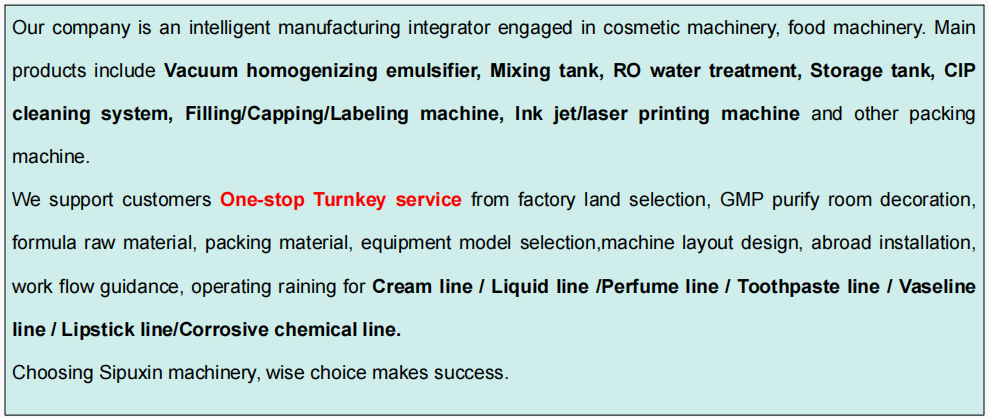

Company Profile

|

Certifications

English

English