Homogenizer Emulsifier key features:

Product name:Vacuum Homogenizing Emulsifying Mixer

Heating method:Electric Steam Heating

Control:Button Panel/PLC Control System

Homogenizer Speed:0-3600 R/min

Mixing speed:0-65 R/min

Function:Stirring emulsification

Keyword:Cosmetics Manufacturing Equipement

Usage:emulsifier

Application scope:cosmetic,food,Chemicals

Opening way:Electric

Production description:

Vacuum Homogeneous Emulsifier is composed of main tank(emulsifying tank),a water tank and an oil tank, vacuum system, up-and down system, electrical control system and the motor frame etc.

This machine is 5 Liter Samll Capacity Liquid Soap Shampoo Cream Homogenizer Emulsifier.

The main pot is composed of the cut-off mixing pot, cut-off mixer unit, circulating system and the stirring system etc. Cosmetic homogenizing machine means that when the materials are under the vacuum condition, it makes use of the high shear emulsifier to distribute one or several to another continuous phase rapidly and evenly.

The product mainly applied in such industries as daily chemical care products, biopharmacutical industry, food industry, paint and ink ,nanometer materials, petrochemical.

Production details:

Top Accessories

accessories designed for observation and mixing are versatile and valuable components in production processes. They enhance quality control, process monitoring, and safety through observation functions. Simultaneously, they optimize mixing efficiency and protect material integrity during the production process. This combination of functions contributes to smoother, more reliable, and higher-quality manufacturing operations.

Mixing paddle

homogenizer, both with adjustable speeds through Variable Frequency Drives (VFDs), offers a versatile and efficient solution for various mixing and homogenizing tasks in industrial processes.

Having both a wall-scraper mixer and a bottom homogenizer in one setup allows for a wide range of processing tasks. From gentle mixing to high-shear homogenization, this configuration can handle various applications within a single machine.

the integration of a top wall-scraper mixer and a bottom homogenizer with VFD-adjustable speeds offers a flexible and efficient solution for various mixing and homogenizing tasks. It combines versatility, precision, time efficiency, and product quality, making it a valuable asset in industrial processes.

homogenizer motor

Indeed, high-speed homogenization is a powerful process that enables thorough mixing, emulsification, dispersion, and homogenization of various materials.

The benefits of high-speed homogenization include enhanced product quality, improved texture, extended shelf life, and increased stability. It's widely utilized in industries where product consistency and uniformity are paramount. However, it's essential to carefully control the process parameters, such as speed, pressure, and temperature, to achieve the desired results without compromising the product's integrity.

high-speed homogenization is a versatile technique that plays a vital role in various industries, allowing for complete mixing, emulsification, dispersion, and homogenization of materials, resulting in high-quality products with consistent properties.

PLC Control Panel

Utilizing a touch-screen control panel with Siemens components is a choice that offers high-quality performance and user-friendly functionality. the integration of Siemens touch-screen controls into your equipment offers a host of advantages, including quality assurance, user-friendliness, adjustable frequency, quick responsiveness, multilingual support, and customization options. This results in an efficient and reliable control system that enhances both productivity and operator satisfaction.

High Shear Homogenizer

A machine with a wide range of spindle speeds, adjustable from 1 to 3000 RPM (Revolutions Per Minute), is highly versatile and suitable for a broad spectrum of applications, particularly in dispersing and shearing both liquid and solid raw materials. Here's how this speed adjustability contributes to its versatility and utility:

a machine with an adjustable spindle speed ranging from 1 to 3000 RPM offers versatility and adaptability in the processing of both liquid and solid raw materials. This flexibility allows for precise control, improved efficiency, and enhanced product quality across a wide range of industrial applications.

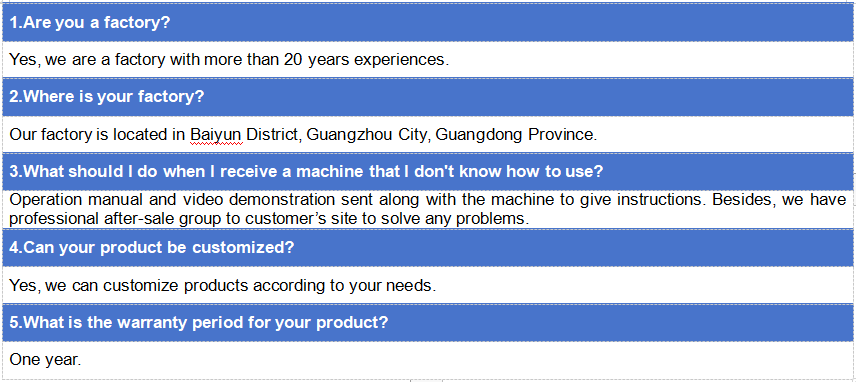

FAQ

English

English