8 heads servo motor filling machine +Straight line cap rolling machine+double side labeling machine+Heat Shrink Film Machine

SpuXin Liquid Washing and Filling Line is a comprehensive automated system designed and manufactured by Guangzhou SpuXin Light Industry Machinery Equipment Co., Ltd. The line is capable of washing, filling, capping, and labeling liquid products such as water, juice, and carbonated drinks. This efficient and precise line is equipped with advanced technology and high-quality components to ensure product quality and maximize production capacity. The SpuXin Liquid Washing and Filling Line is the ideal choice for businesses seeking reliable and efficient automation solutions for their liquid filling needs.

.Details description

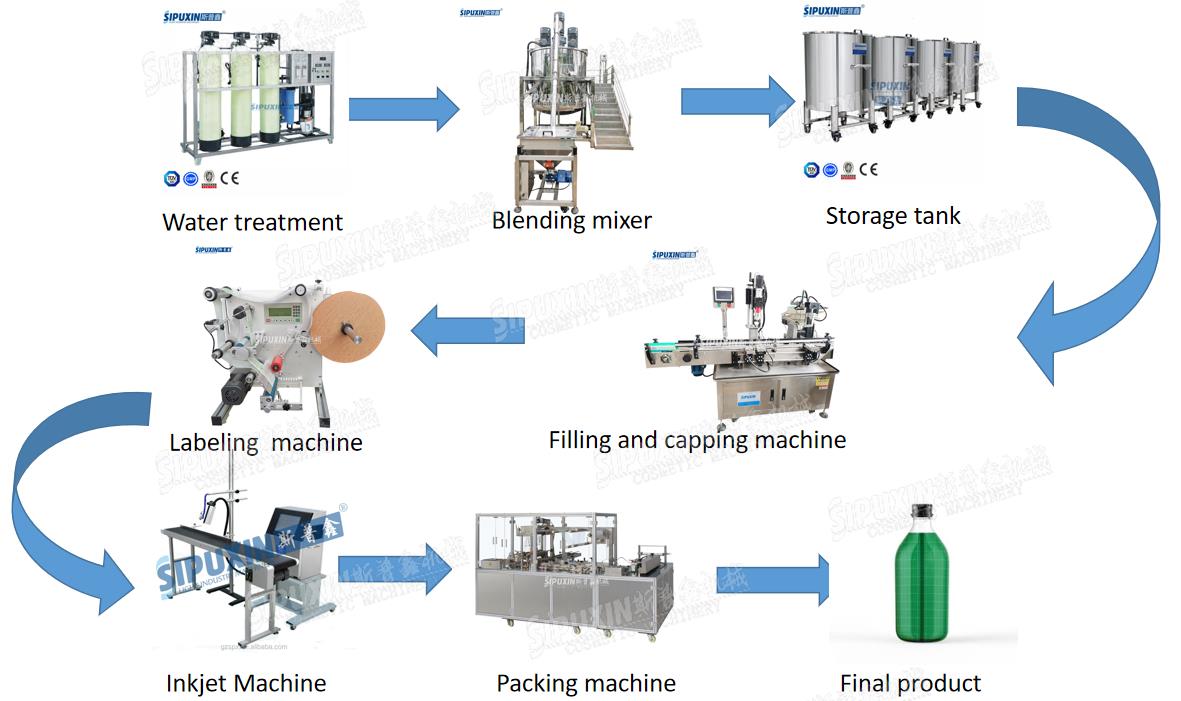

The SIPUXIN liquid washing and filling production line is a high-efficiency equipment system designed to meet the needs of modern industrial production. This production line is suitable for filling various liquids, such as water, juice, carbonated drinks, and other beverages. The production line is equipped with advanced technologies, including automatic filling, capping, and labeling functions, to ensure the precision and accuracy of the production process.

The production line is made up of several individual machines that work together seamlessly. The first machine is the bottle-washing machine, which uses a high-pressure water jet to clean the inside and outside of the bottles. The next machine is the filling machine, which uses a precise filling valve to fill the bottles with the desired liquid. The third machine is the capping machine, which automatically caps the bottles with a screw cap or a snap-on cap, depending on the design of the bottle. The final machine is the labeling machine, which can label the bottles with a range of information, including the product name, manufacturer, expiration date, and more.

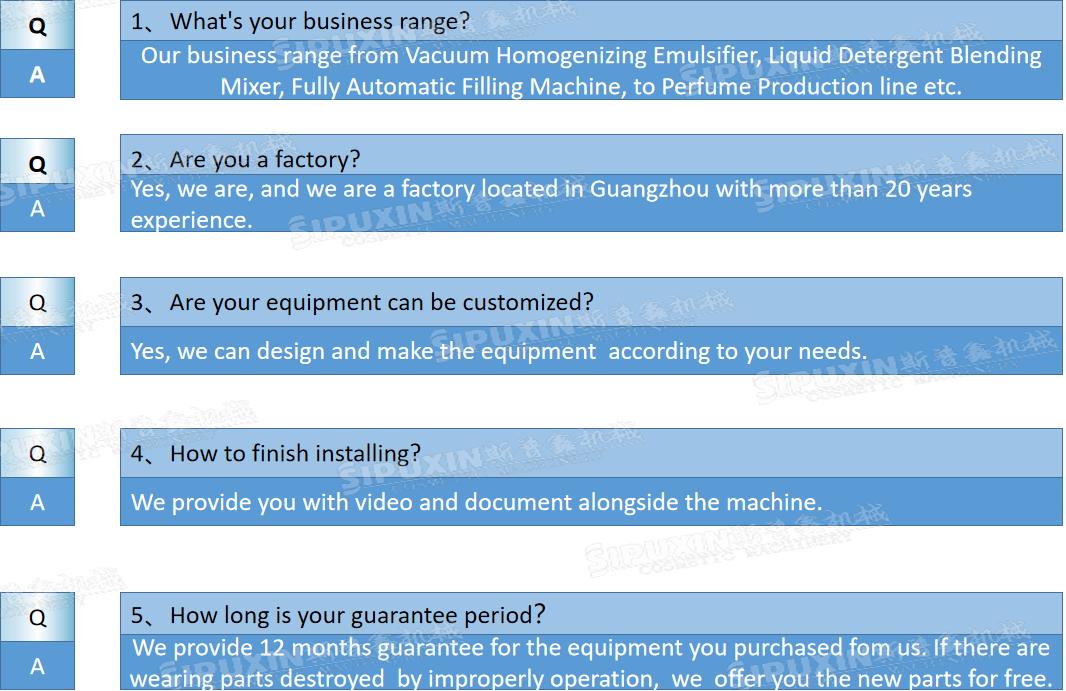

The SIPUXIN liquid washing and filling production line has a high degree of automation, which ensures that the production line can operate smoothly with minimal human intervention, thus improving efficiency and reducing labor costs. The production line can be customized to meet the specific needs of different businesses, including different bottle sizes, shapes, and materials. With its reliable performance, high efficiency, and flexible customization options, the SIPUXIN liquid washing and filling production line is an ideal solution for manufacturers looking to increase their production capacity and improve their bottom line.

Advantages of the Spuxin liquid washing and filling complete line:

1. High efficiency: The Spuxin line is designed to be highly efficient, with a high-speed filling and capping system that can fill and cap a large number of bottles quickly and accurately.

2. Precision filling: The Spuxin line uses advanced filling technology to ensure that each bottle is filled accurately to the required level, minimizing waste and ensuring consistent product quality.

3. Easy to operate: The Spuxin line is designed to be easy to operate, with an intuitive control panel and simple maintenance procedures, ensuring maximum productivity with minimal downtime.

4. Flexible configuration: The Spuxin line can be configured to suit a wide range of products and packaging formats, allowing for maximum flexibility and adaptability to changing market needs.

5. Robust construction: The Spuxin line is built to last, with high-quality components and a rugged design that can withstand the rigours of continuous use in demanding production environments.

Similar product process+filling+labeling process

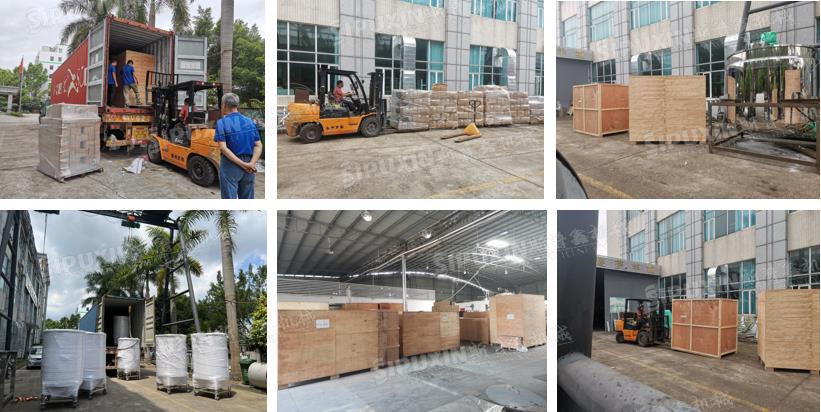

We use plywood to pack the goods, which can not only better protect the goods in transit, but also prevent insects from biting the board.High on-time delivery rate, well packed.

English

English