Product overview

Introduction of SPX 6-head servo filling line by Guangzhou SPX Light Industrial Machinery Equipment Co., Ltd.

The SPX 6-head servo filling line is a high-performance and efficient equipment designed for accurate and reliable liquid filling. It is equipped with six servo motors to control the filling volume and speed precisely, ensuring consistent and uniform filling results.

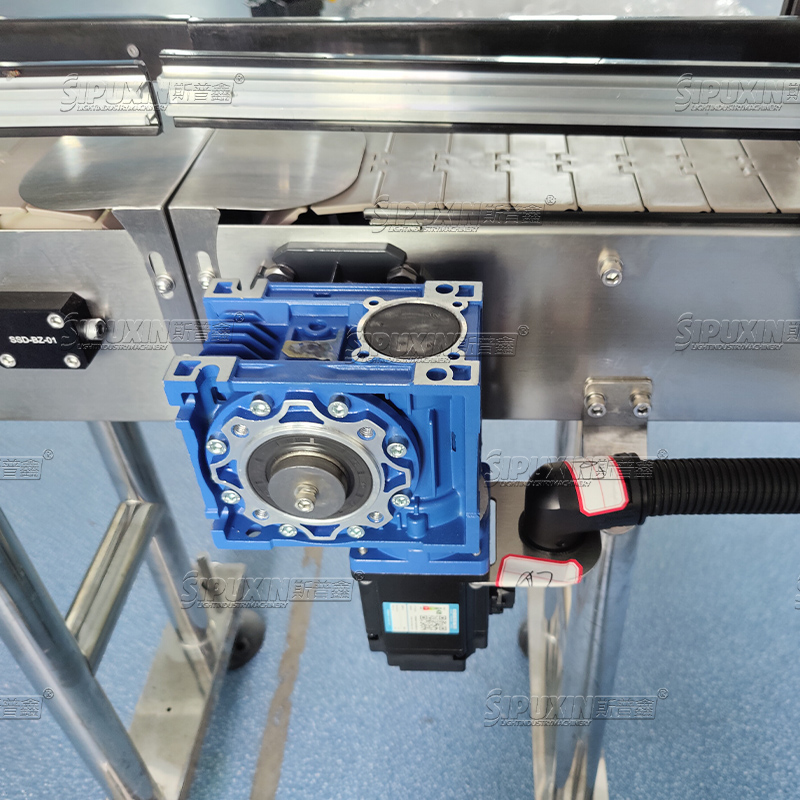

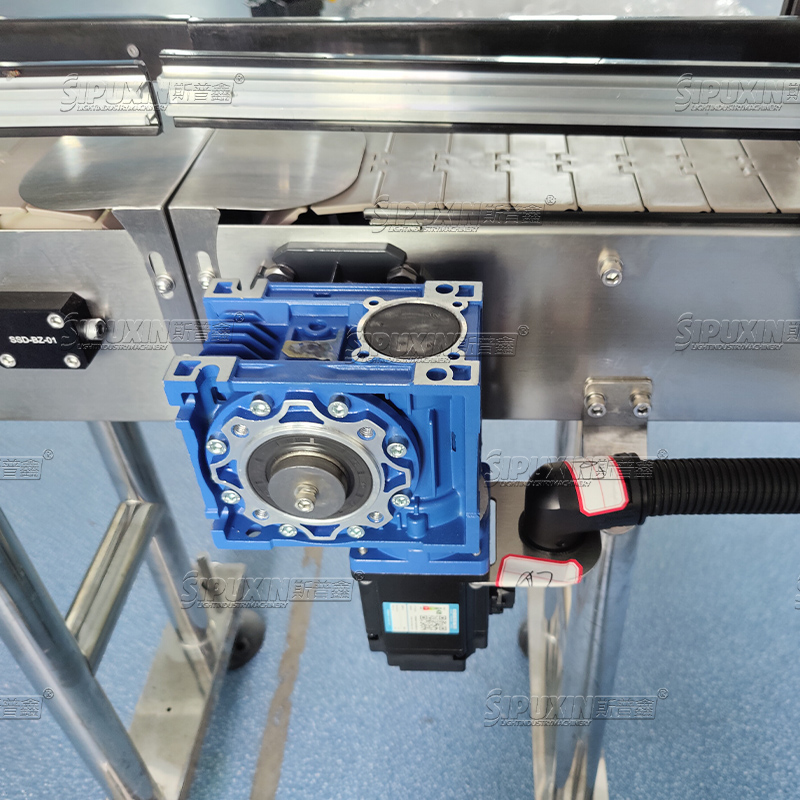

The machine is made of high-quality stainless steel and features a user-friendly touch screen interface for easy operation and maintenance. It can handle a variety of liquid products such as oil, sauce, and beverage with different viscosity levels.

With its advanced technology and reliable performance, the SPX 6-head servo filling line is widely used in industries such as food, beverage, and pharmaceuticals. It is an essential equipment for manufacturers who value quality and efficiency in their production processes.

Cap dropper, cap dropping on bottle tops

Round bottle labeling machine part, the choice of labeling machine is a round bottle labeling machine, round bottle labeling machine specializing in labeling round bottles, labeling, rotating tug labels

Feature

Guangzhou Supexin Light Industry Machinery Equipment Co., Ltd.

The Supexin 6-head servo filling line is characterized by:

1. High precision: The use of servo control technology ensures accuracy and consistency of filling volume.

2. Wide range of applications: The filling line can be used for various types of liquids, such as juices, beverages, oils, sauces, and other non-corrosive liquids.

3. Efficient: The use of servo motors ensures high-speed filling, reducing filling time and increasing production efficiency.

4. User-friendly: Easy-to-use touch screen control panel and automatic control system makes operation easy and convenient.

5. Hygienic: The filling line is made of stainless steel, which is easy to clean and maintain, and meets food industry standards.

6. Flexible: The filling line can be customized according to customer requirements in terms of filling volume, number of heads, and other specifications.

Advantage

"Guangzhou Supexin Light Industry Machinery Equipment Co., Ltd."

Compared to peers, our Supexin 6-head servo filling line offers the following advantages:

1. Higher Accuracy: Our servo motors provide precise filling and allow for on-the-fly adjustment to achieve the desired volume, resulting in a filling accuracy rate of ±0.3%, which is higher than that of our competitors.

2. Greater Efficiency: With a production capacity of up to 3600 bottles per hour, our Supexin filling line reduces labor costs and increases production efficiency compared to similar systems in the market.

3. Customizable Configuration: Our 6-head servo filling line is equipped with high-quality stainless steel valves and fittings, customizable bottle conveyor, and filling speed, which can be tailored to meet customer needs.

4. User-Friendly Control: Our filling line is designed with a user-friendly interface, which allows for easy operation and monitoring of the filling process. Furthermore, it offers real-time feedback on filling performance, reducing the possibility of mistakes.

5. High Quality: We use premium materials and advanced manufacturing processes to ensure that our Supexin filling line is of the highest quality. This guarantees its durability, long lifespan, and minimal need for maintenance.

Overall, the Supexin 6-head servo filling line is the ideal solution for customers who require precision, efficiency, and user-friendliness in their manufacturing process.

English

English