SPX 300L Hydraulic Lift Vaccum Homogenizer Emulsifying Machine key features:

Product name:SPX 300L Hydraulic Lifting Type Electric Heating Vaccum Homogenizer Emulsifying Machine

Function:Homogenzing and emulsifying

Heating method:Electric Heating

Control:Button Panel

Homogenizer Speed:0-3600 R/min

Stirring speed:0-65 R/min

Keyword:Vaccum homogenizing emulsifier

Application scope:cosmetic,food,Chemicals

Type:Homogenizer Making Machine

Application scope:cosmetic,food,Chemicals

After-sales Service Provided:Overseas Service Provided

Production description:

Introducing the 300L Horizontal Bar Hydraulic Vacuum Homogenizer Emulsifying Machine, the perfect solution for your high viscosity product mixing needs. This professional-grade machine features a variety of essential components, including a mixing main pot, water and oil pot, vacuum system, hydraulic lifting system, top cover, mixing blade, control panel, and dispersing blade.

Designed to handle the mixing, dispersing, and emulsifying of thick products such as facial creams, sunscreens, and eye creams, this machine is a must-have for any cosmetic or pharmaceutical manufacturer. The hydraulic lifting system allows for easy adjustment of the mixing pot, while the vacuum system ensures a thorough and consistent blend.

With its robust construction and user-friendly controls, the 300L Single-Bar Hydraulic Vacuum Homogenizer Emulsifying Machine is the ideal choice for any professional looking to streamline their production process and achieve exceptional results. Invest in quality and efficiency with this top-of-the-line mixing machine.

Production details:

Top Accessories

Components and Functions:

1.Sight glass device: Observe the material inside tank;

2.Suction device: Using the vacuum through transfer tube/ pipe sucking the material into the main tank;

3. Vacuum induction device: Mainly used for lifting design, when the vacuum in the main tank to a certain state, it can avoid the tank cover go up (warning: Lifting is forbidden under vacuum condition!) ;

4.Vacuum device: Used for vacuum the material inside the main tank, we install a one-way valve for easy operation;

5. Sight glass lamp: We install the sight glass to facilitate the observation of the operation in a machine for convenient observation;

6.Air breather: To avoid the air composition outside the tank into the tank inside when under the work conditions;

7.Cleaning device: Used for clean the tank after each production, and the cleaning ball can to be 360 swiveled for cleaning;

8.Vacuum pressure gauge: Used for observe the tank inside’s vacuum degree, and can set the tank inside’s vacuum degree according to it;

9.Spices bucket: Used for add certain spices or additive;

The mixing system

Normally mixing structure is devised into frame-wall scrapping mixer, Two-way mixer, and helical ribbon agitator mixer etc. structure. Our this agitator is frame wall scrapping agitator, center and side-sweeper agitator mixing, along with Teflon plate scrapping the wall.

The mixing speed is controlled by frequency converter.During mixing, the inner impeller and outer frame paddle is in anti-direction.

Alarm:

Before turn on water tank mixing, confirm first if the tank is with upper mixer or bottom mixer, if it is bottom mixer, make sure there is sufficient water ( at least 1/3) in tank that can turn on the mixer, otherwise the mechanical sealing of bottom mixer will be damaged, or even lead to motor short circuit because liquid leak into motor

Button operation panel

Buttons are easy to identify, convenient for the operator to operate various functions, press these buttons to control the machine start or stop operation; you can also adjust the parameters. At the same time, the components used can guarantee the quality of the equipment and prolong the service life.

Homogenizer

Homogenizing system structure:

Normally there are Upper homogenizer, Bottom homogenizer, Cycling homogenizer.

Homogenizer is consist of motor, rotor and stator.

Homogenizersealing adopts special double faces mechanical sealing and skeleton seal,

mechanical seal adopts tap water cycle cooling.

Homogenizer working principle:

Motor drive the high speed rotating rotor by the special clutch and high speed main shaft, materials distribute one or several phases to another continuous phase rapidly and evently,

the materials will be proceeded in the narrow space between stator and rotor by strong

energy of motion produced by the mechanical effect.Meanwhile, materials are mixing with speed above 12m/s in the outside region of rotor( special design can be up to 60m/s or even higher speed), Under the stator resistance force, materials are strongly shearing, crashing etc. thus to achieve dispersing, emulsifying.

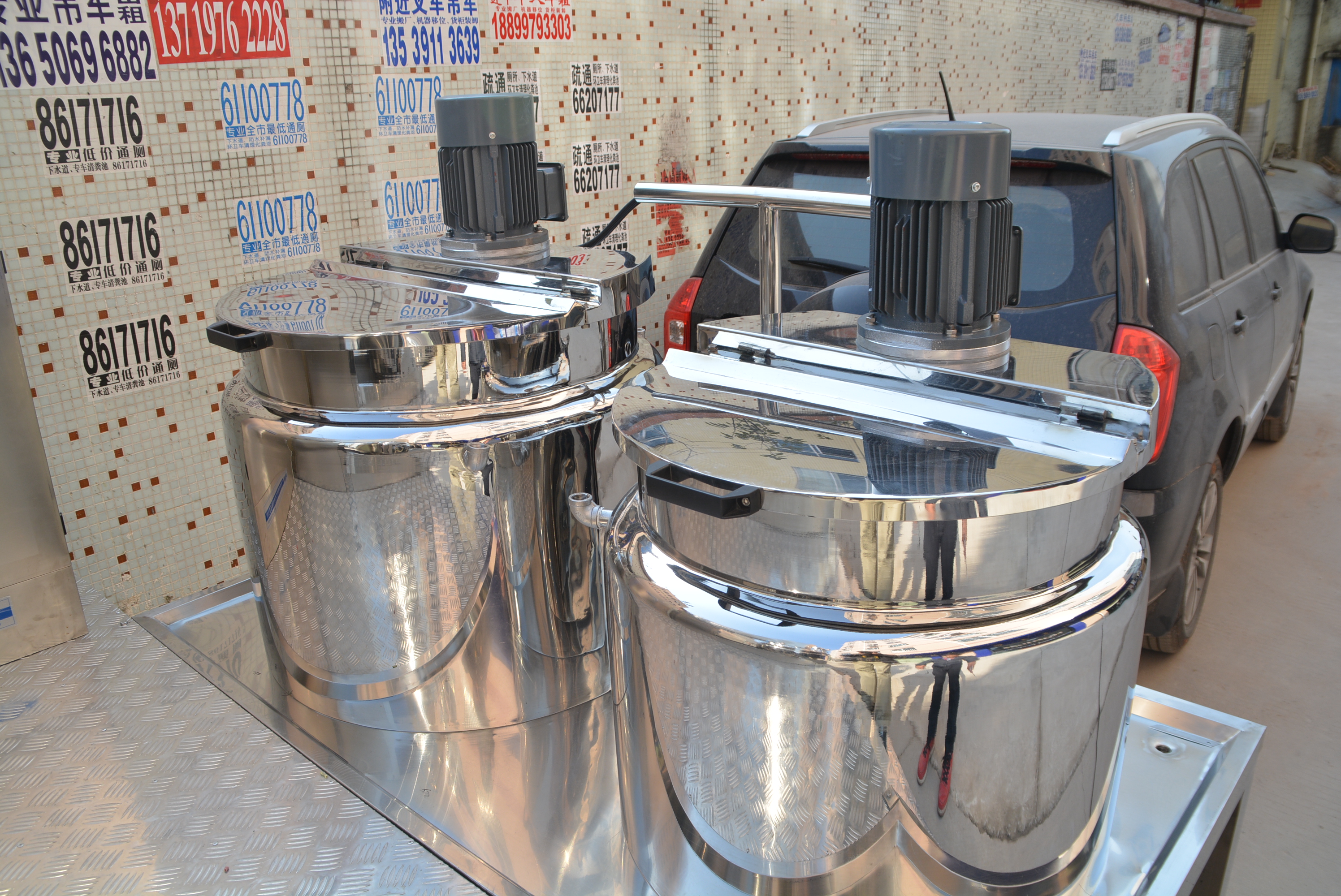

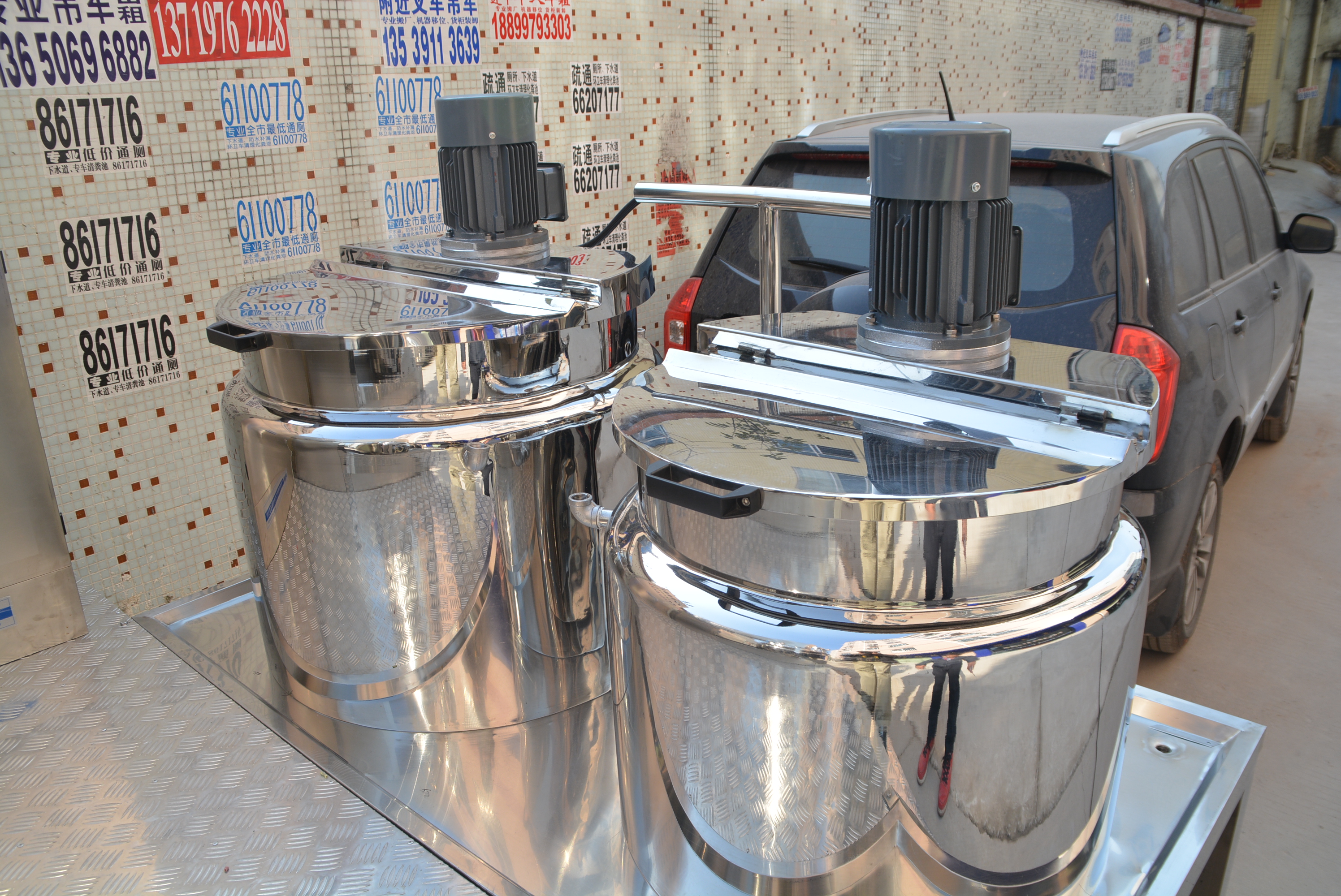

Oil tank and water tank

Function: Pre-heating pre-stirring

Size: water pot large oil pot small

Rotational speed: 960RPM / min (non-adjustable)

English

English