1. The homogeneous vacuum emulsifier generates a linear velocity of at least 15m/s or above at the outer end of the high-speed rotating rotor, which can reach 40m/s, and forms strong mechanical and hydraulic shear, liquid layer friction, impact and tearing, allowing the material to be fully dispersed, emulsified, homogenized, crushed, and simultaneously ejected through the stator slot.

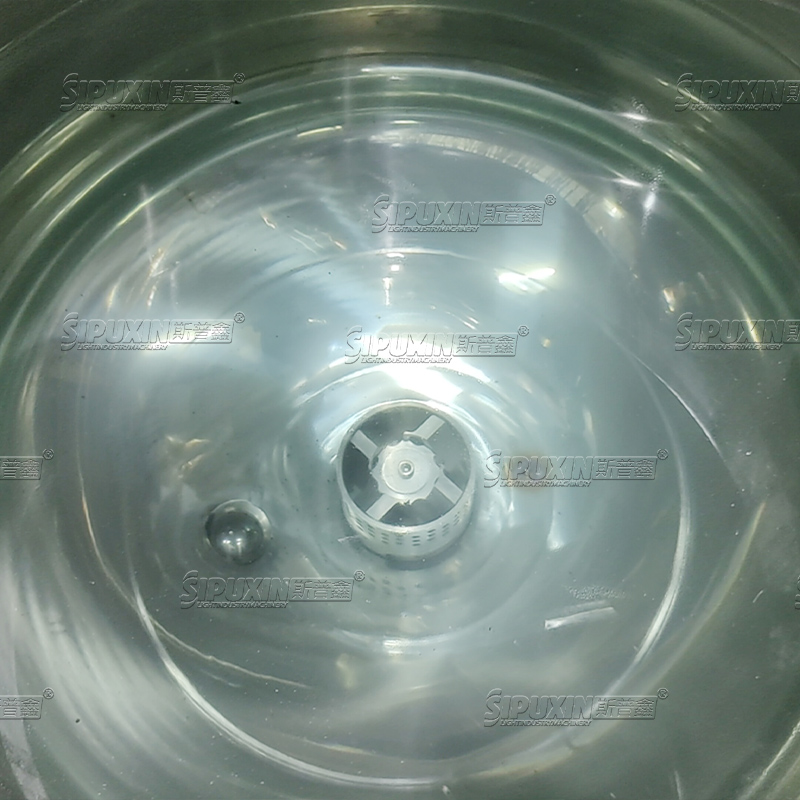

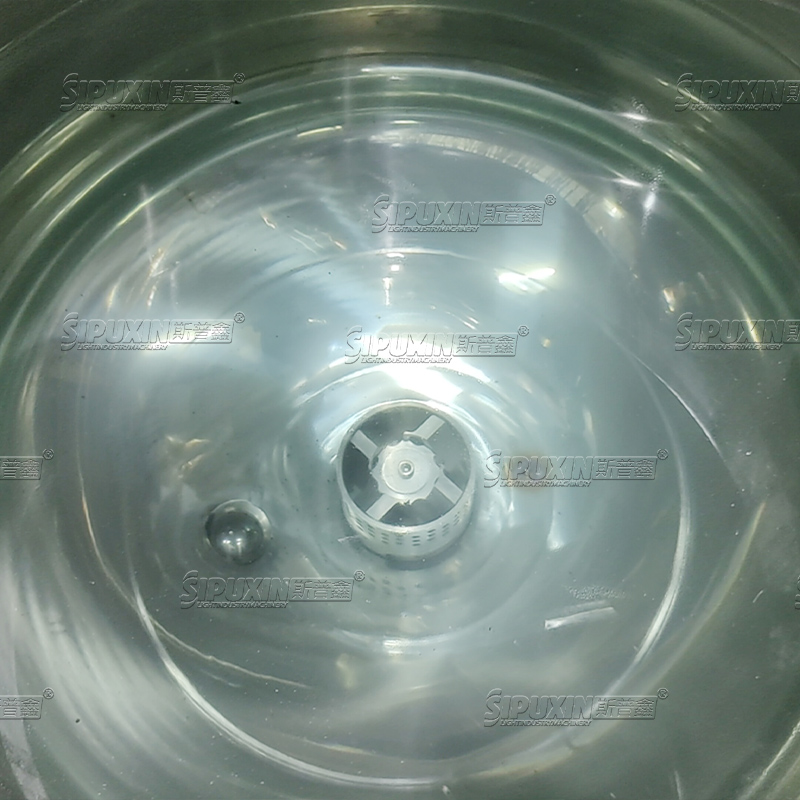

2. Under the centrifugal force generated by the high-speed rotating rotor of the homogeneous vacuum emulsifier, the material is simultaneously sucked into the working chamber axially from the upper and lower feeding areas of the working head.

3. The strong centrifugal force throws the material radially into the narrow and precise gap between the stator and rotor. Simultaneously subjected to centrifugal compression, impact and other forces, the material is initially dispersed and emulsified.

4. The homogeneous vacuum emulsifier continuously ejects materials from the radial direction at high speed, changing the flow direction under the resistance of the material itself and the container wall. At the same time, under the action of the upper and lower axial suction forces generated in the rotor area, strong turbulent turbulence is formed in the upper and lower directions. The material undergoes several cycles and ultimately completes the processes of dispersion, emulsification, and homogenization.

English

English