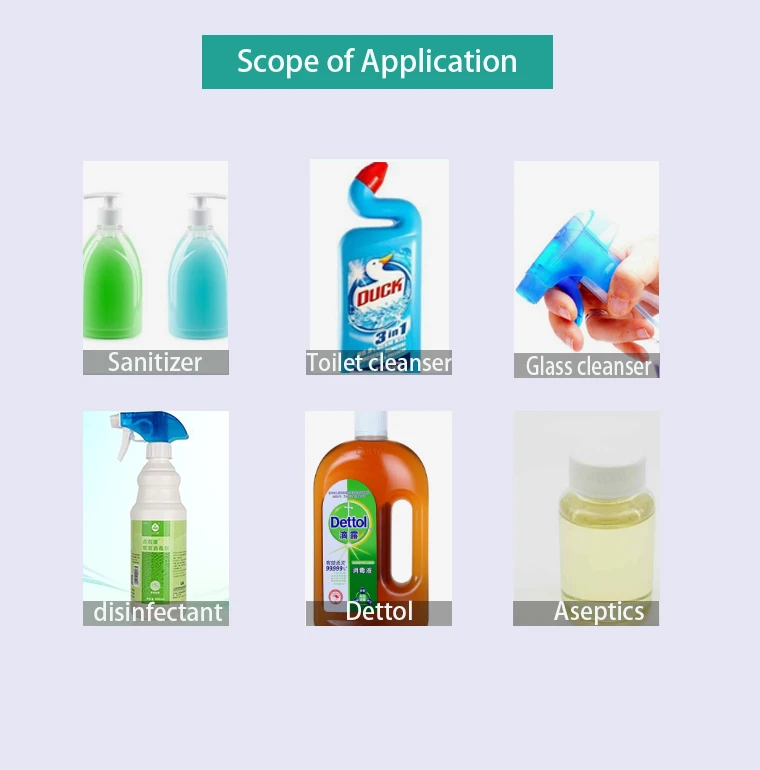

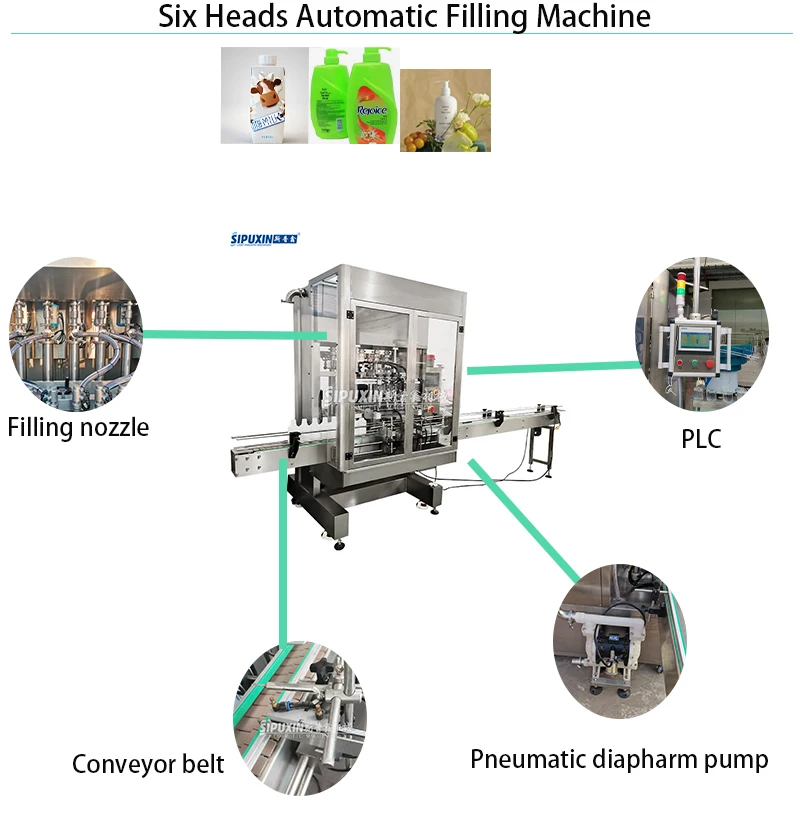

It is used for automatic filling of various liquids into bottles. Such as shampoo, laundry detergent, shower gel, detergent,tomato sauce, sauces, lubricants,cooking oil, etc. It is suitable for filling in large quantities of factories, and can be connected to the production line before and after.

It can be used together with the capping machine, capping machine, labeling machine and inkjet printer.

According to the production requirements, single head, 2 heads, 4 heads, 6 heads, 8 heads, etc. can be selected.

English

English