| ◤ Guangzhou Sipuxin Light Industry Machinery Co., Ltd. is an intelligent manufacturing integrator engaged in cosmetic machinery, pharmaceutical equipment, food machinery.

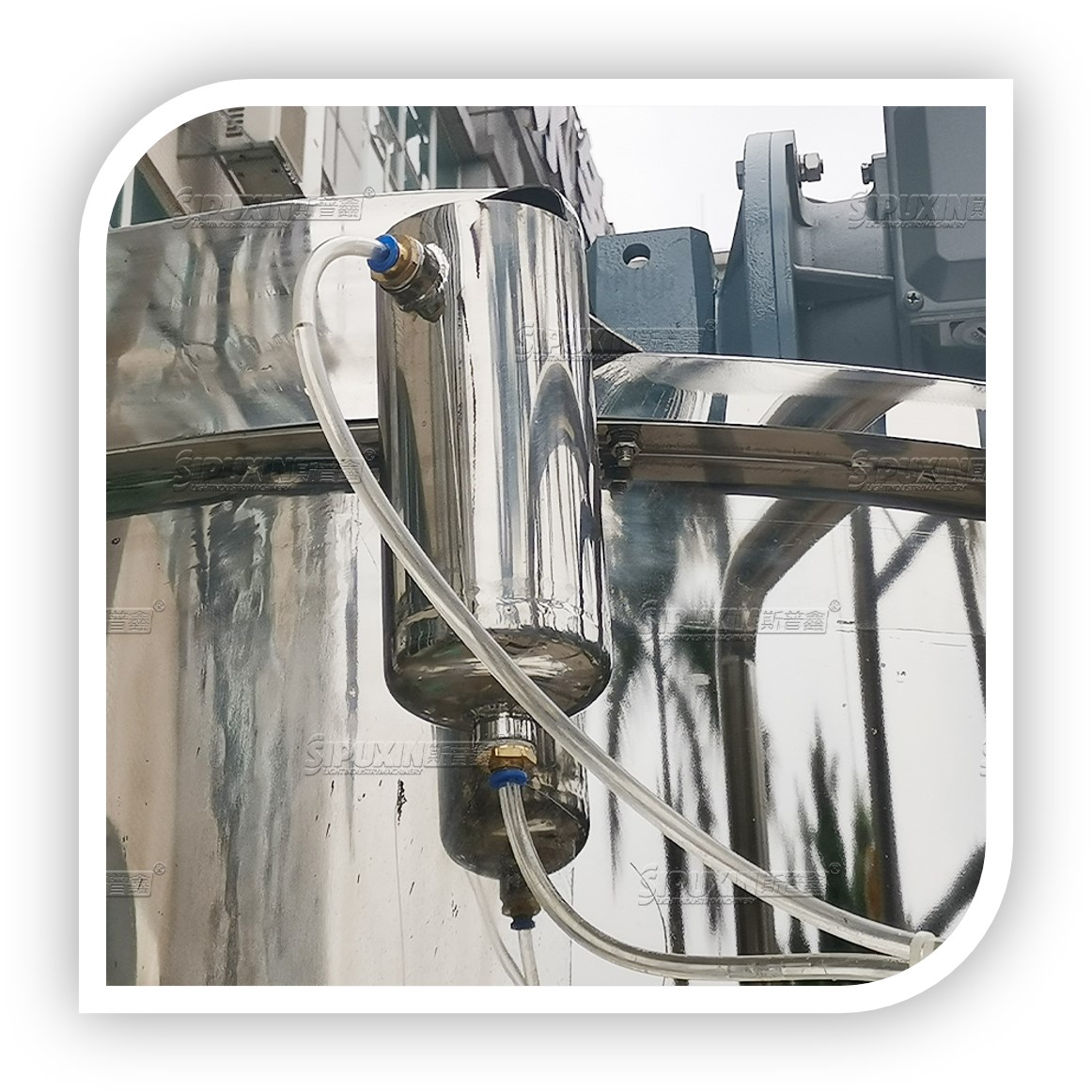

Modern factory in Yangzhou occupies 10000+ square meters, Guangzhou factory occupies 9000+ square meters. Through CAD and 3D dynamic simulation. More than 500 designs in 2000+ square meters modern showrooms. Sipuxin is able to customize new equipment according to client's customization request. Sipuxin has introduced advanced production equipment, invested to upgrade hardware facilities, strictly controlled quality, and refined testing procedures.

The main production lines are: cream production line, Liquid detergent production line, perfume production line, toothpaste production line, wax production line, lipstick production line, Handmade soap production lines, etc., cover the entire daily chemical food and pharmaceutical industries. Main products include Vacuumhomogenizing emulsifier, Mixing tank, RO water treatment, Storagetank, Filling/Capping/Labeling machine, Ink jet/laser printing machine and other diversified high-quality stand-alone machines, Create the brand strength of Sipuxin. ◢ |

English

English